Our Commitment to Excellence Is an Act of Care

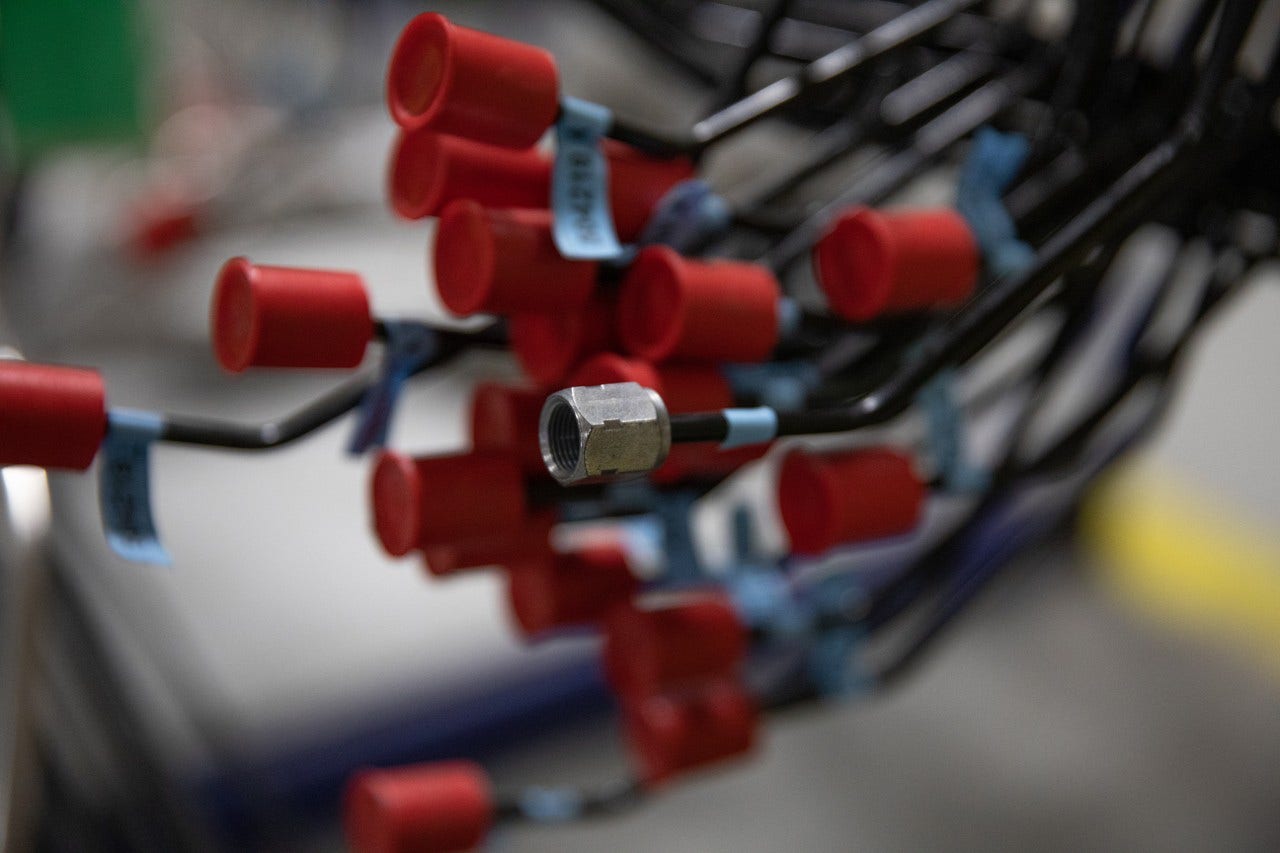

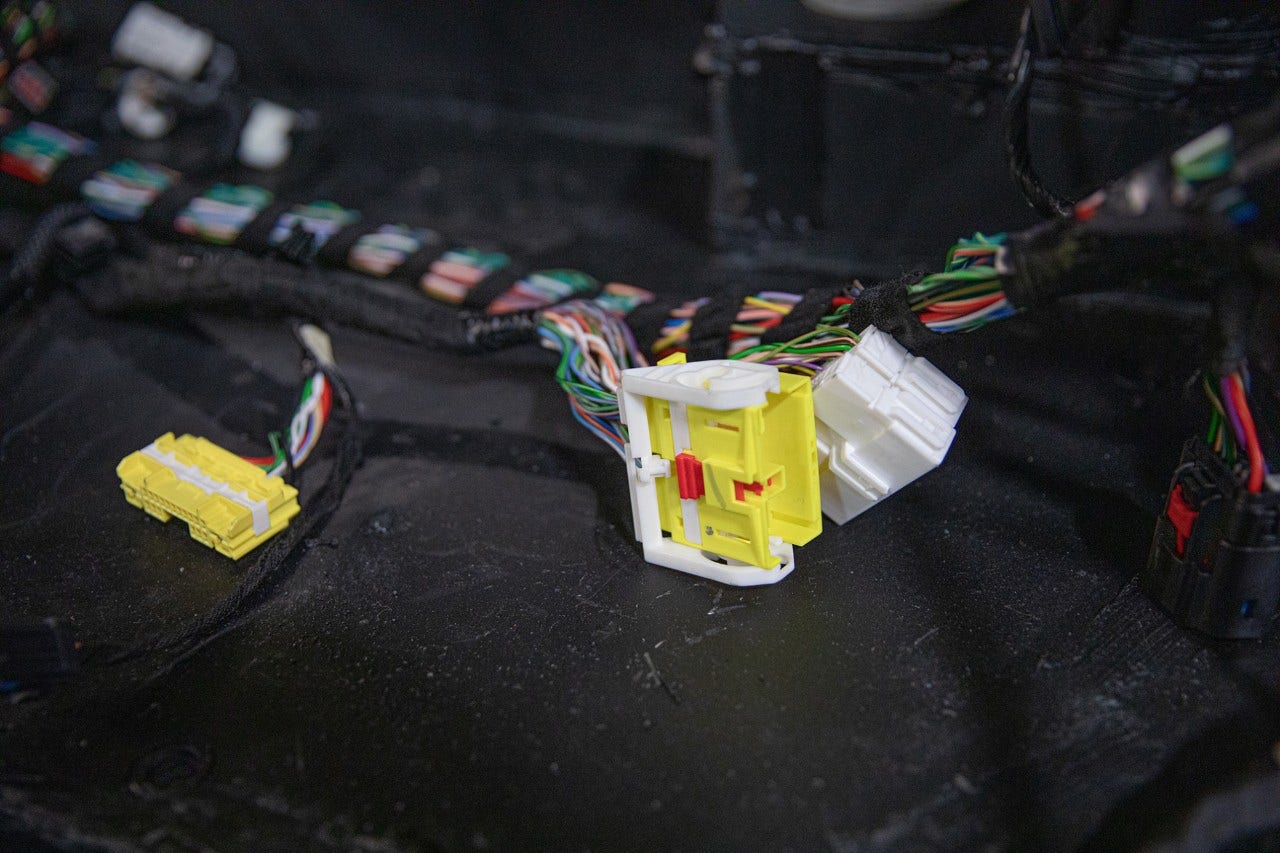

Our mission is to build a more inclusive world, and it starts with a quality product. That’s why BraunAbility engineers invest at least 15,000 hours in every accessible vehicle and utilize advanced engineering technology and software, including:

- Finite Elemental Analysis to predict potential weak points in vehicle design before crash testing

- Tolerance Stack-Up Software allowing engineers to visualize tolerances and variations in design

- Robotic Spot Welding for precise seams and vehicle performance

- Parametric Modeling and Simulation for accurate testing of mechanisms and components

- Continuous Improvement Team dedicated to enhancing and refining in-market products to constantly upgrade the BraunAbility ownership experience for our customers